SHOCK

INCLINATION

VIBRATION

TEMPERATURE

HUMIDITY

PRESSURE

GPS TRACKING

LIGHT INCIDENT

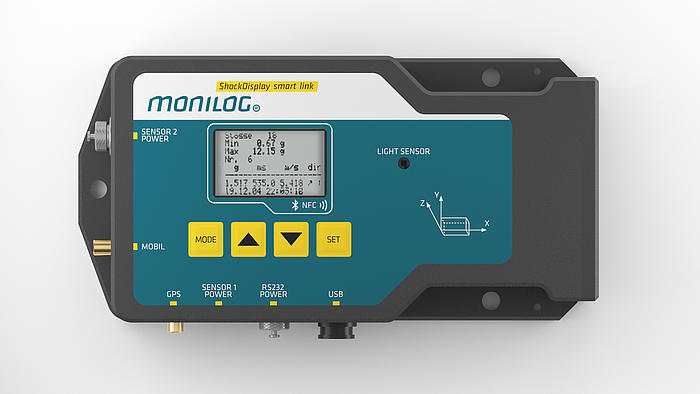

- Extremely robust shock recorder with realtime tracking

- Registers all mechanical shock events and stores the 100 largest with signal progress

- Measures direction, strength, time, duration, minimum and maximum of the effect

- 24/7 data access in MONILOG® web portal

- status report with Bluetooth or NFC

- GPS receiver for precise positioning and Inclination measurement on board

- Easy operation, display, alarm function, long operating time

- external sensors for temperature, air humidity and pressure

- Tamper-proof, multi-level password protection

- Conformity with all relevant norms and standards for measurement of transport shocks

Product description:

- Online tracking data logger fully equipped plus up to 2 independent external sensors. Ideal for monitoring complex transports and for long-term checking of large plants

and machines. Power transformers, generators, turbines or switchgear have a highly precise manufactured and sensitive inner life. - Highly sensitive shock sensors record all mechanical shock events and store the 100 largest with the direction, strength, time, duration, minimum and maximum of the eff ect.

- Also inclinations, such as the rolling of a ship, are measured.

- A complete signal progressionis documented for each shock and inclination event.

- The ShockDisplay smart LINK determines the exact position via an integrated GPS receiver.

- With an external sensor, further data such as temperature, relative humidity and absolute air pressure can be recorded in parallel – important for transport under protective gas or for temperature-sensitive and moisture-sensitive transport goods.

- 24/7 data access in the MONILOG® web portal and convenient readout of the status report using the MONILOG® Connect app.

- Tampering is excluded by means of a multi-level password protection, internal memory support, checksums and logging of all processes relevant for the measurement data acquisition.

- With the device, the causes of transport damage can be precisely determined over very long periods of time.

- The ShockDisplay smart LINK meets all standards and guidelines for shock measurement and transport monitoring.

Technical data:

Housing:

Aluminium, hard-anodized • degree of protection IP67; weight: 1.07 kg including alkaline batteries • 42 g each magnetic base; size: 198 x 100 x 44 mm (D x W x H) • Ø 32 x 7 mm² (small magnetic base); surface mounting (3-point screwed connection recommended), magnetic foot mountings optiona

Operation and storage conditions:

-20°C to +60°C with alkaline batteries; -40°C to +85°C with lithium batteries

Data memory, time:

Data receipt for a minimum of 10 years, independent of battery status; 32 MB flash parameter and data storage; date/time as world time UTC, supported by the internal battery, exchange at the manufacturer after 6 years needed

Power supply:

Internal: 2 batteries type D or R20 replaceable; Alkaline batteries (2 x 1.5 V, 16,000 mAh) • lithium batteries (2 x 3.6 V, 17,000 mAh) • Operating time up to 3 years, typically 1 year (for alkaline batteries, all options active with relevant settings);

External: Mini-USB AB 5 V • external voltage supply (6 - 24 V, < 15 W) via IP67 connector (to RS232 / Power)

Mobile connectivity

Frequency ranges:

LTE Cat 1, globally compatible with LTE, UMTS/HSPA(+) and GSM/GPRS/EDGE • Measurement data sent worldwide by e-mail and/or visualisation in the "MONILOG® web portal"

Dual SIM card:

Accepts 1.8 V or 3 V micro SIM card •

Alternative use of an embedded SIM

Bluetooth

Bluetooth Low Energy BLE 5.2 • Status report can be read out with smartphone and free "MONILOG® Connect" app • Save and send the PDF report by email

Connections:

USB 2.0 Client (Mini-USB AB) • RS232 via IP67 five-pole connector (for optional use) • Analog input: connection for analog pressure sensor

GPS receiver:

32 satellite channels (GPS, SBAS, BeiDou, QZSS) • SMA socket for connection of an external active antenna 50 Ω 3 to 30 mA, 3 V (rod or cable antenna) • 25,000 data records, tolerance 100 m

Display and operating elements:

illuminated LCD display, indication of: date, time, room vector, integrated shock strength and duration, minimum, maximum, number of shock and inclination events; multilingual and password-protected menu navigation

Acceleration and shock:

14 g (3 axes, 3,200 Hz, tolerance ± 0.32 g) • configurable digital signal filtering • when the registration threshold is exceeded, shock curves are recorded • the 500 highest shock curves are stored • optional: 30 g, 1,600 Hz, tolerance ± 0.6 g or 60 g, 1,600 Hz, tolerance ± 1.2 g)

Inclination measurement:

Inclination calculation from static acceleration • when the registration threshold is exceeded, up to 640 inclination curves (12 Hz, 8 s, tolerance ±3°) are recorded according to the event • additionally continous inclination recording adjustable in interval between 1 minute and 24 hours • 200,000 data records

Temperature:

-40°C to +85°C • tolerance ±0.5 K • 200,000 data records

Relative humidity:

0% – 100% RH • tolerance ±2% RH (on 20 ... 80% RH) • 200,000 data records

Air pressure:

260 – 1,260 mbar • ±2 mbar tolerance (optional: 10 – 2,000 mbar, ±4 mbar tolerance) • 200,000 data records • when connecting an external pressure sensor, the external pressure is stored

Light:

0 lx - 65,000 lx • tolerance ±15 % • 200,000 data records

Configurable parameters:

Shock registration thresholds x, y, z • minimum shock duration, shock strength • limit for inclination, temperature, humidity, pressure • alarm indication on the display • intervals for continuous measurement of GPS, inclination, temperature, humidity and pressure • password for reading, configuring, On/Off switching • Start/Stop time for the data recording

Conformity:

Device approval according to CE, UKCA;

shock evaluation according to DIN EN 15433-6, RoHS, WEEE;

Frequency analysis according to DIN EN 13011;

use according to IEEE C 57.150-2012